Single-phase liquid cooling methods are highly effective when convection air cooling is unable to remove the heat load required to keep devices below their safe maximum operating temperature. For applications requiring high heat flux or high-power electronics cooling, liquid-cooled cold plates are frequently employed.

Kingka Business For the highest possible liquid cold plate thermal performance, using Hi-Contact technology maximizes the region where liquid tubes and a cooling surface come into touch. In order to reduce interface resistance between all contact surfaces our proprietary geometry is used in these designs to provide the greatest amount of contact between a tube and a plate and a device.

Kingka is a reputable custom liquid cold plate producer in the field of cooling systems offering solutions for thermal management systems in new energy cars. We have a technical team that years of R&D and manufacturing experience with heat sinks for liquid cold plates.

Designing Of Liquid Cold Plates

There are a number of obstacles to go through while creating a liquid cold plate in order to achieve the best results. There are frequent trade-offs between different design possibilities. Kingka has a lot of expertise in satisfying thermal requirements while lowering operational and production costs. We will examine the following critical performance characteristics as part of the design:

● Low pressure

● Path of liquid flow

● Stream balancing

● Compatibility of materials

● Dynamic Stability

● Temperature Consistency

● Maximum Temperature Size

● Weight

Liquid Cold Plate with Welding Process

➢ Extrusion methods are employed to directly construct the flow passageways of the cold plate and connect the flow passages by machining any blockages that can be utilized to friction stir weld liquid cold plate.

➢ Friction welding which has a rapid rate of production and cheap cost, is used to seal the assembly.

➢ Due to the limitations placed on the flow passageways this technology is not appropriate for applications requiring higher power densities or having an excessive number of screw holes on the surface.

➢ The primary uses for integrated cooling goods like conventional power modules are in power batteries cooling heating appliances, and heating equipment.

➢ Additionally, there is more flexibility in designing the internal passageways’ sizes and paths.

➢ Depending on the application conditions, a variety of liquids and water cold plate techniques are available for choice.

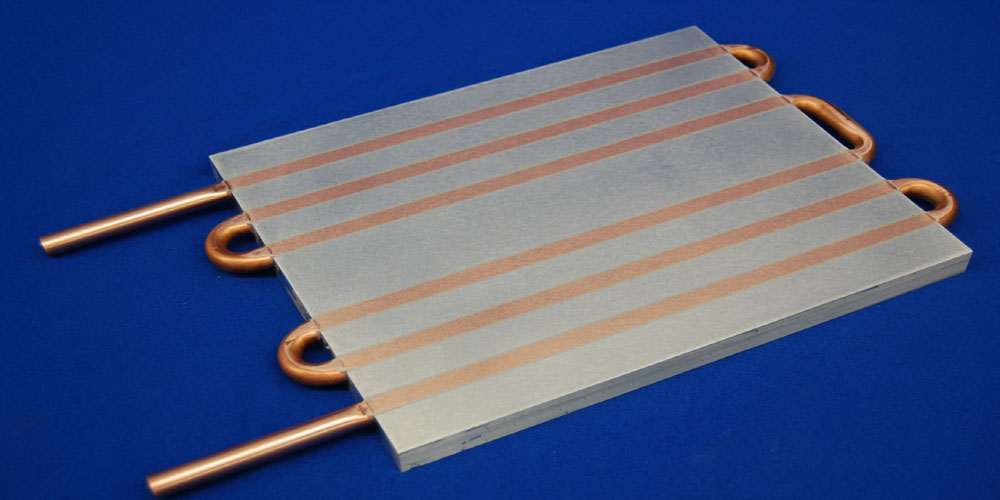

● Buried-Tube Technique

Devices that need to be put on one side can use this method. After being forced into the grooves of an aluminum plate copper tubes are deformed, and the surface is then given a fly-cut.

Due to copper tubes’ high thermal conductivity this enables fast heat removal. While this is happening, lightweight aluminum can help keep costs down and overall weight down.

● Micro-Channels with Friction Welding

The flow passageways of the chilly plate are immediately formed using extrusion processes, and any obstructions are machined out of the way to join the flow passages. Friction welding, which has a high production throughput and cheap cost, is used to seal the assembly.

Due to the limitations placed on the flow passageways this technology is not appropriate for applications requiring higher power densities or having an excessive number of screw holes on the surface.

Last Wording

A type of effective heat sink for IGBT, GTO, and other potent components is the liquid cold plate. It has the ability to regulate the power module temperature so that it does not rise above the maximum temperature allowed by the standard and specification when it is being used. The liquid cooling plate has a water circulation system integrated into it, and the electronic parts are mounted directly to the plate.