Starting a new business is not easy. You need deep knowledge and experience for it. If you want to start a new business and don’t know what type of business brings profit, choose the biomass pellet line. Wood pellet is high in demand and can give you a profitable future.

Starting a wood pellet production line is a good deal because all over the world, the demand for wood pellets is high and expected to increase every coming year.

Read this article to learn some great tips and tricks to help you establish a wood pellet production line. We hope this will help you and you can earn a great living from this.

Step-By-Step Guide to Build a Wood Pellet Production Line

First Step: Stable Raw Material Supply

The first and the most important step when you want to establish a wood pellet production line is finding great quality raw material. You can contact different farm owners to use agricultural waste like rice husk, cotton stalks, crop straw, and grass.

It is important to get a great quality raw material because getting a high-level moisture content material for pellet making can cost you more. Because you need to spend additional costs on drying, choose the material wisely.

Second Step: Locate the Area for Production Line

Make sure to get the area that should be large enough to hold the production of wood pellets, storage of raw material, and transportation. It should be better to check electricity because large-scale equipment like drum dryers and pellet machines needs more electricity to run smoothly.

The other factors that affect your production business are water source and traffic convenience. Locating your wood pellet line near the raw material supply is recommended. This way, you can cut your transportation cost and make more profit.

Third Step: Layout for Wood Pellet Line

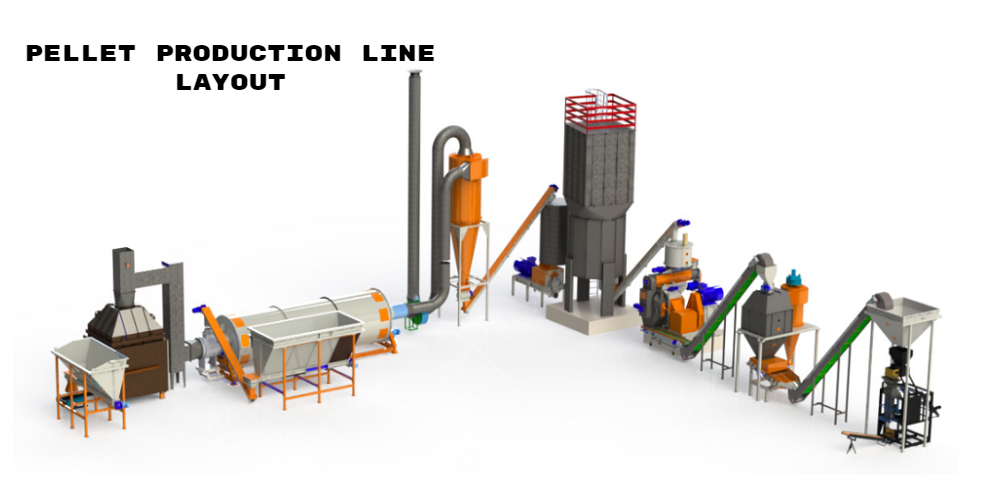

The layout of every production factory plays an important role in its success or failure. You should get professional help while preparing to open a production line. Processing equipment should be arranged according to its structure and maintenance capacity.

Always place core equipment near the window to easily see full production operation. Divide the area among raw material, production line, and pellet storage after reviewing all facts and figures. Check all safety precautions to prevent any kind of accident.

Fourth Step: Install Production Equipment

Buy quality production equipment with suitable working capacity according to your needs. Make sure your equipment can work 24/7 with a high-efficiency rate. It is recommended to locate production equipment that has obtained CE certificates.

Fifth Step: Hire Staff

Without manpower, no factory can work when you make everything assembled; it’s time to recruit staff according to your production scale.

Six-Step: Develop Your Customers

Now it is time to focus on developing your wood pellet market to ensure your sales and profits. You can target national and international markets. But we recommend you focus on the area that has cold weather most of the time because people in these areas use wood pellets to heat their houses and cooking ranges.

Conclusion

Above, we have discussed how you can start a wood pellet production line by finding a stable raw material supply. The most important thing for a successful production line is that your factory layout is perfect and airy with the right safety measures.

We hope this information helps you start a wood pellet production line that can bring a lot of profit for you.