Multi-fiber Push-On (MPO) connectors were invented several years ago, and are used all around the world. It was created to reduce the time spent in fusing sliced individual connectors. After these connectors are fused, a lot of space is created.

How does the MPO connector look like?

Every MPO connector has a key on one side of the body. If the key sits at the bottom, it is called the key-down position. When it sits on top, it is called the key-up position. This orientation entails that each of these fiber holes is numbered in a particular sequence, from left to right.

We call these connector holes positions, or simply denote as P1, P2, etc. There is also an additional white dot on each connector that shows where the first position (or P1) is when plugged in.

Types of MPO connectors

These connectors were originally manufactured for ribbon fibers. As time went by, they began to produce them in different variants- 12, 24, 48, and 72 variants. But the 12-fiber and 24-fiber MPO connectors are the most popular and widely used. So, we will be looking at each of them in detail.

12-fiber connectors

A 12-fiber connector can transmit and receive 6×10 fibers. They are called transceivers. However, these transceivers and equipment were only able to support 40G data rates, rather than the 60G data rates they were supposed to support. So, there is a problem.

This means that 33% of these fibers are not used. In this 12-fiber connector, only 8 fibers are being used at the transceiver. The 4 remaining fibers are spare. This is why 12-fiber connectors could not be used in the long run.

It was simply the first connector to perform at an acceptable rate in data centers. It could offer 12 times its density when connected, which created more space in the racks. Most data centers are built with 12-fiber MPO cables at the back that connects to other equipment like servers and switches.

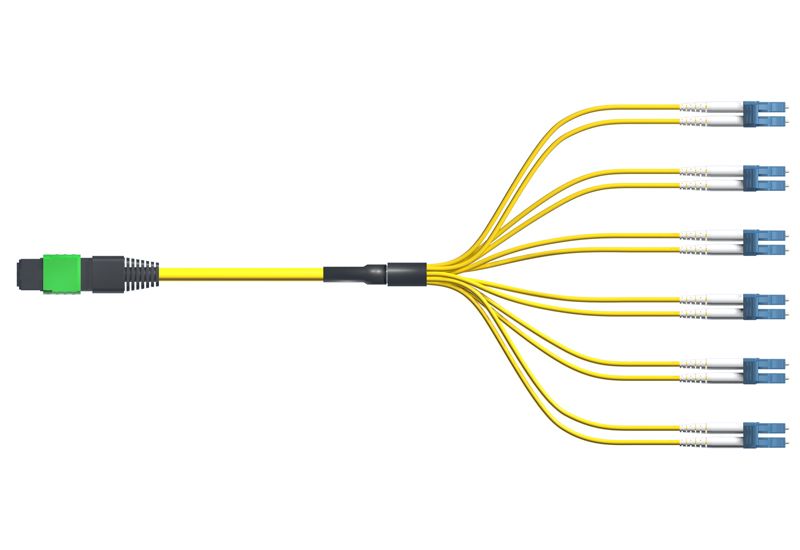

Some equipment today still have LC transceiver interfaces. This means that the harness has to convert from MPO to LC at that point.

24-fiber connectors

Companies began to realize that 12-fiber connectors could no longer provide the needed requirements for data and telecom centers. All equipment coming into these centers were either 24 fibers (100G) or 8 fibers (40G). 24 is divisible by 12, but not 8.

If 2×12 fibers MPO connectors are joined at the backbone, you can as well connect 3×8 MPO connectors, and no fiber is wasted. This 24-fiber MPO connector performs almost the same as the 12, if not the same.

The 24-fiber MPO connector consists of two rows of 12 fibers. This additional row of fibers needs an increase in the spring force to fuse all these fibers together. You not only get double effects, and reduces the cables needed at the backbone.

Companies figured that they could combine 1×24 fibers, instead of 2×12 or 3×8 fibers.

There are many other types of MPO Connectors as well, for example, MPO Breakout Cable. You can find more information if interested.