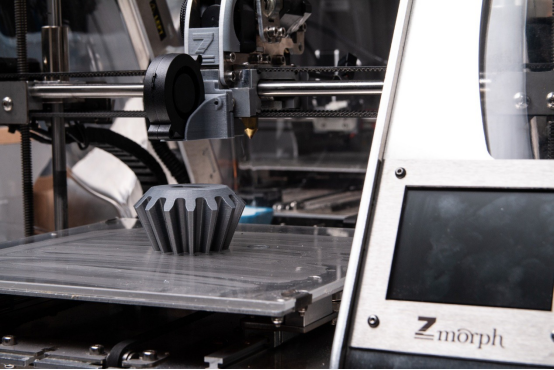

The 3D printing technology is gaining traction for its effectiveness in creating solid models. The process of creating these models isn’t entirely straightforward as there are certain things to be put into consideration when operating. Usually, the success of your 3D object prints depends on how meticulous you are in following the required steps.

One of the fundamental aspects of 3D printing is bed leveling on the printer. Bed leveling is an aspect of printing that corrects certain anomalies in the axis orientation of the printer. There are several varieties of bed leveling procedures, and this article highlights ways through which you can handle this vital aspect of 3D printing.

Ensure the Nozzle tip is clean

Right before you begin your next printing operation, you must check for residual particles on the nozzle tip. A brass brush is usually ideal in carrying out this operation to guarantee success. It’s essential to wipe the nozzle mildly with the brass brush to avoid any damages to the nozzle. Careful adherence must be paid to proper safety precautions while cleaning the hot end of the nozzle.

Adjust the manual bed leveling printers

Many 3D printers incorporate the manual form of bed leveling as it’s often believed that it guarantees precision. Manual 3D printers involve the use of specific screws in adjusting the bed level of the printer until the required standard is achieved. The number of screws varies according to the printer as some printers have three screws while others have four. Each screw has a dedicated direction in which it turns the bed, and the mastery of each screw could make a lot of difference. Here are a few tips to aid your use of manual bed leveling printers;

- Create enough workspace between the build plate and the nozzle by tightening the screws

- Ensure the nozzle and the workplate are well placed

- Calibrate the tip of the nozzle and adjust the screws to this effect

- Make necessary adjustments to the nozzle cap

- Check the adjustments by trying to print the first layer of your job

The Bed surface should be clean

The bed surface of the 3D printer has to be cleaned after adjusting the nozzle and other parameters. Debris and particles usually settle on the surface after previous printing jobs, and these particles could affect the shape of the next object to be printed. You mustn’t make use of your bare hands in cleaning the bed surface as this might leave oil stains on the bed. An excellent way to remove such particles is via the use of spatulas; these spatulas are especially suitable for cleaning hard bed surfaces. In a situation where the spatula might damage the bed surface, the use of solvents like isopropyl alcohol might suffice.

Final thought

The use of 3D printers in making solid objects is quite advantageous in many ways. However, certain 3D printers require manual bed leveling to get desirable results at the end of the process. This article lists some of those tips that could prove helpful while printing; however, a free-leveling 3D printer might not require manual bed leveling as they have mechanisms in place to perform this operation.